Ultrasonic Testing

Mechanical / Non-Destructive Testing (NDT)

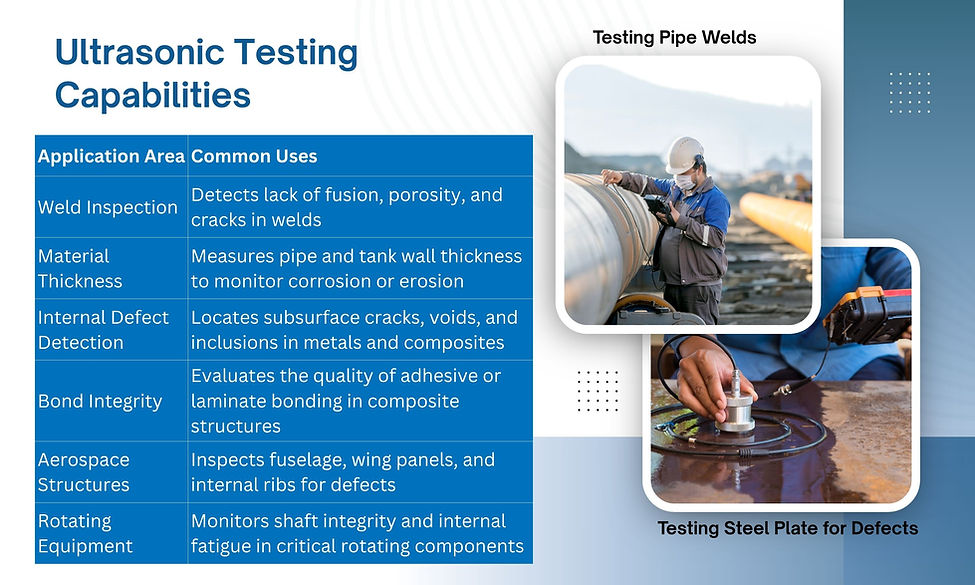

Ultrasonic Testing (UT) is a non-destructive testing method that uses high-frequency sound waves to detect internal flaws, material thickness, or discontinuities in components. Commonly used in manufacturing, aerospace, energy, and infrastructure, UT enables early fault detection by identifying cracks, voids, or corrosion beneath the surface, making it invaluable for inspecting welds, pressure vessels, pipelines, and structural parts without causing damage.

When to

Use

Common Use Cases

Flaw Detection in Metals & Welds

Identifying cracks, voids, porosity, or lack of fusion in welds.

Detecting fatigue cracks in structural members.Thickness Measurement

Checking pipe walls, tanks, and pressure vessels for corrosion or erosion.

Measuring remaining wall thickness without cutting or dismantling.Bond Integrity Checks

Inspecting composite materials for delaminations.

Verifying adhesive bonds in aerospace, automotive, or manufacturing applications.High-Value or Safety-Critical Components

Turbine blades, aircraft fuselages, bridges, and load-bearing machine parts.

Components where failure could cause catastrophic damage or safety hazards.After Repairs or Modifications

Confirming weld repairs meet specification before returning equipment to service.

Verifying no hidden defects remain after re-machining.When Other NDT Methods Aren’t Practical

When magnetic particle testing isn’t possible due to non-ferrous material.

When X-ray is too expensive, slow, or presents radiation safety issues.