Unlocking Component Failures: Understanding Failure Fingerprints for Enhanced Longevity and Performance

- Kerin Epperly, CLSSMBB

- Sep 28, 2025

- 3 min read

In today's fast-paced engineering and maintenance landscape, knowing why components fail is not just important, it’s vital to ensure lasting performance and reliability. One of the most powerful tools at our disposal is the analysis of failure fingerprints. These fingerprints document the unique conditions and stressors that lead to a component's failure. By examining these indicators, we can predict failures and implement crucial preventive measures.

In this article, we will discuss failure fingerprints, how they help us understand failure modes, and specific steps we can take to enhance component health and increase reliability.

What Are Failure Fingerprints?

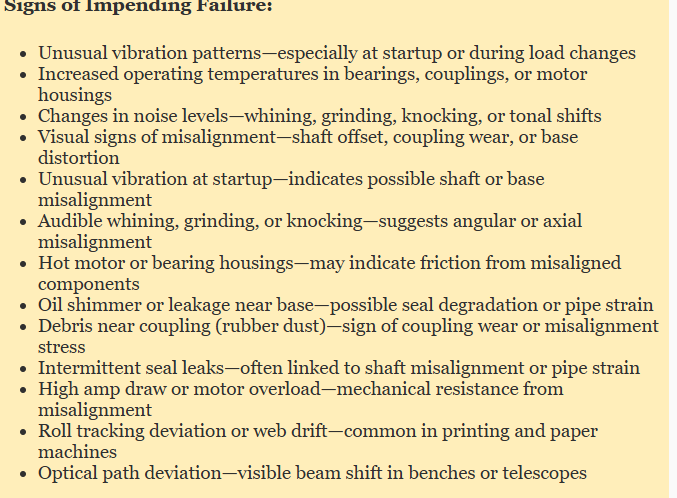

Failure fingerprints are detailed records formed by analyzing a component's failure history. They reveal the exact conditions, stressors, and environments that cause components to degrade. By evaluating these fingerprints, engineers can find patterns that indicate when and why a component is likely to fail.

For example, in a manufacturing plant, a motor may exhibit failure fingerprints that show it consistently fails under extreme heat and heavy load. By recognizing these conditions, maintenance teams can schedule regular cooling system checks and load assessments to preempt failures.

Understanding these fingerprints is critical for proactive maintenance. This insight allows organizations to act before failures occur, improving response times for repairs and replacements.

The Importance of Analyzing Failure Modes

Analyzing failure modes is essential for understanding failure fingerprints. Failure modes describe the different ways components can fail, like fatigue, corrosion, or wear. By categorizing these failure modes, engineers can identify root causes and devise targeted solutions.

Consider a scenario where a hydraulic pump consistently fails due to wear. This issue might arise from being operated beyond its design limits or from poor lubrication. Identifying this specific failure mode allows the maintenance team to fine-tune the operating parameters and adjust lubrication schedules, thus significantly reducing future failures.

Moreover, this level of analysis helps prioritize maintenance tasks. Focusing on components that show the highest risk of failure ensures that resources are used efficiently, ultimately enhancing equipment reliability and reducing unexpected downtime.

Predicting When Failures Will Occur

Understanding failure fingerprints significantly enhances our ability to predict when failures may occur. By examining past failure data and observing trends, organizations can develop effective predictive maintenance schedules tailored to their equipment's unique requirements.

For example, if analysis shows that a specific type of bearing fails consistently after 1,000 hours of operation under certain conditions, maintenance teams can schedule replacements at 900 hours. This strategy helps avoid unexpected machine breakdowns, which can incur costs upwards of $5,000 per hour in lost production.

Mitigating Stressors to Prevent Premature Failures

After identifying failure fingerprints and modes, the next step is to tackle the stressors that lead to premature failures. Key strategies include:

Regular Inspections: Implementing routine checks can catch early signs of wear, allowing maintenance teams to act quickly.

Environmental Controls: Monitoring and controlling factors like temperature and humidity can greatly improve component longevity. For example, reducing humidity in storage areas can prevent corrosion-related failures.

Load Management: Ensuring components operate within their specified limits can help avoid fatigue-related breakdowns. Motor overload can lead to a 50% increase in wear rates.

By addressing these stressors, organizations create a better environment for their components, thus extending their service life and enhancing overall equipment health.

The Role of Technology in Failure Analysis

Modern technology has changed how we analyze failure fingerprints. Tools like predictive analytics, machine learning, and IoT sensors allow organizations to collect and analyze data in real time. This data-driven method leads to more precise predictions and a better understanding of component health.

For example, IoT sensors can continuously monitor the temperature and vibration levels of machinery. If a sensor detects anomalies, maintenance teams can investigate potential issues before they escalate, reducing unplanned downtime by up to 30%.

Final Thoughts

Knowing how to interpret failure fingerprints can profoundly impact the longevity and effectiveness of components. By investigating failure modes, predicting potential failures, and addressing stressors, organizations can improve their maintenance strategies and overall equipment health.

As technology continues to advance, our capacity to analyze failure fingerprints will become increasingly sophisticated. Embracing these innovations enables better decision-making, reduced downtime, and enhanced operational efficiency.

In an era where equipment reliability is key, understanding failure fingerprints is essential for organizations aiming to lead in their industries. By uncovering the secrets of component failures, we can build a path toward a more resilient and efficient future.

Comments