The Three Pillars of Equipment Health: Form, Function, and Fit

- Kerin Epperly, CLSSMBB

- Sep 6, 2025

- 3 min read

With over 25 years navigating the intricacies of manufacturing, I've found that the health and reliability of our equipment, the very backbone of production, can be distilled into three fundamental concepts: Form, Function, and Fit. Understanding and balancing these elements is not just good practice; it’s the key to unlocking improved performance, anticipating failures, and driving continuous improvement across the shop floor and in operational data alike.

Form: The Physical Integrity

Form refers to the physical condition and shape of a component or piece of equipment. It's about whether the equipment is structurally sound, free from damage, and conforms to its intended physical specifications. This includes aspects like material integrity, surface finish, absence of cracks, proper dimensions, and overall physical appearance.

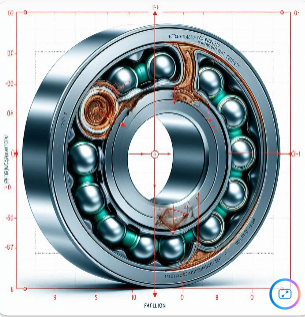

Think of a ball bearing. Its Form is impeccable when its races are smooth, its balls are spherical and unblemished, and there are no visible signs of wear, corrosion, or damage. If the outer race is cracked or a ball is dented, its Form is compromised, immediately signaling a potential problem.

Function: The Operational Capability

Function is about what the equipment is designed to do and whether it is performing its intended task correctly and efficiently. This element focuses on the operational capabilities, performance metrics, and adherence to process parameters. Is the equipment performing its job as expected?

For our ball bearing, Function means it's smoothly and quietly rotating, allowing the shaft it supports to spin freely with minimal resistance and vibration. If the bearing is noisy, binds, or causes excessive vibration, its Function is impaired, even if its Form appears superficially intact. This could be due to internal wear, lubrication issues, or improper installation.

Fit: The Interconnectedness

Fit addresses how well a component or piece of equipment integrates and interacts with its surrounding system. It's about the compatibility, alignment, and proper relationship with other parts, assemblies, and the overall operational environment. Does it belong, and does it work harmoniously with its surroundings?

In the case of the ball bearing, Fit is crucial. It must be the correct size and type for the shaft and housing it’s installed in. It needs to be properly seated (not too tight, not too loose) and aligned with the shaft and any other components. A bearing that's too large, too small, or misaligned will not only fail prematurely itself but can also damage adjacent components and negatively impact the entire machine’s operation. Even a perfect Form and Function can be rendered useless if the Fit is wrong.

The Synergy of Form, Function, and Fit

True equipment health is achieved when Form, Function, and Fit are all in balance. A component can look perfect (good Form), but if it doesn't perform its task (poor Function) or doesn't integrate correctly with its system (poor Fit), it's a ticking time bomb. Conversely, a component that seems to be Functioning might be masking underlying issues in its Form or Fit, leading to accelerated wear and unexpected failures.

By consistently assessing these three elements – inspecting for damage (Form), monitoring performance (Function), and verifying integration (Fit)

Form – the blueprint, the build and design.

Function – the ability to perform consistently and reliably.

Fit – the integration, blending seamlessly with others.

Applying these to a ball bearing:

Its form is defect-free races and balls.

Its function is smooth, low-friction rotation under load.

Its fit is proper seating, aligned shafts, and seals working together.

we move from reactive firefighting to proactive maintenance and reliability. This holistic view allows us to anticipate failures before they occur, diagnose issues with greater accuracy, and implement targeted solutions that drive genuine continuous improvement.

Conclusion

The principles of Form, Function, and Fit provide a clear, accessible framework for understanding and managing equipment health. Whether you’re on the shop floor performing daily checks or in management reviewing performance data, focusing on these three pillars helps ensure our machinery operates reliably, efficiently, and predictably. Embracing this balanced approach is fundamental to minimizing downtime, optimizing productivity, and building a more robust manufacturing operation.

Comments