The 5 Senses: The Amazing Power of Sound

- Kerin Epperly, CLSSMBB

- Sep 18, 2025

- 2 min read

Understanding component failure doesn’t always have to rely on expensive diagnostic tools. In fact, one of the most powerful methods we have at our disposal costs nothing, it’s teaching operators to use their five senses at the GEMBA (the place where the work happens).

When operators are trained to observe, listen, smell, touch, and even notice taste-related cues in the environment, they become the first line of defense against unplanned downtime. Among these, sound is one of the most underutilized yet powerful tools.

The Sound of Failure in Progress

Listen to this sound.

Do you hear it?

At first, it may sound like a normal rotation. But listen closely, there’s an irregular wobble, a faint tapping where the bearing is touching on one side and then the other. That is not the sound of healthy machinery. It is the sound of a bearing nearing the end of its life cycle.

A worn bearing like this is just one step away from failure.

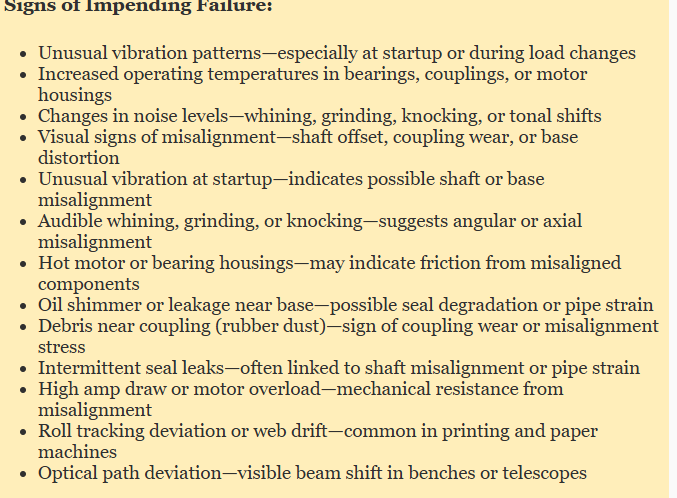

Left unchecked, it can cause:

Shaft misalignment

Secondary damage to housings and gears

A chain reaction leading to catastrophic downtime

Why Operator Training Matters

By training operators to recognize these sounds, we shift from reactive firefighting to proactive control.

Imagine this:

Instead of a bearing failing mid-shift, shutting down production, and creating costly ripple effects…

The operator identifies the abnormal sound early, escalates it, and maintenance schedules a controlled repair.

This transforms catastrophic, unplanned downtime into a perfectly timed repair.

The 5 Senses in Diagnostics

While sound is highlighted here, the other senses are equally valuable at the GEMBA:

Sight – spotting leaks, discoloration, loose bolts, or abnormal vibration.

Smell – detecting burning oil, overheated insulation, or chemical leaks.

Touch – feeling abnormal heat, looseness, or excessive vibration.

Taste (contextual) – in food or process industries, detecting contamination issues.

When combined, these senses empower operators to detect failure fingerprints long before machines stop.

Conclusion

Failure diagnostics doesn’t always require complex equipment or high-end sensors.

Your first diagnostic toolset is already on the shop floor: the eyes, ears, and instincts of your operators.

When they learn to listen to a bearing’s “death rattle,” see discoloration, or smell overheating, they are no longer passive observers.

They become active guardians of uptime.

Start small.

Play the sound of a worn bearing in your next training session.

Ask your operators:

What do you hear?

That simple question might save thousands of dollars in lost production tomorrow.

Here is another sound,

what do you hear this time? Leave your answer in the comments.

Comments