FRAME-D Component Fault Viewer

Fingerprint

40% of Gear Failures

Root cracks, broken teeth

Fine cracks initiate at the tooth root, usually at the fillet where bending stresses concentrate.

Cracks propagate across the tooth width with characteristic beach marks (fatigue striations).

Surface may show rust or oil staining inside cracks (if operating over time).

Final overload fracture appears jagged or crystalline once the remaining cross-section can no longer carry load.

Broken tooth pieces may be found in oil sump or housing.

Prevention Strategy

Tooth Wear Prevention

Proper Lubrication: Always use the correct type and grade of lubricant with regular oil changes to prevent abrasive and adhesive wear.

Clean Environment: Ensure seals are intact to keep dust, dirt, and moisture out; contaminants can greatly accelerate wear.

Material Selection: Use wear-resistant gear materials or add surface hardening (carburizing, nitriding, induction hardening).

Smooth Operation: Avoid excessive vibration or misalignment, which can speed up wear.

Load Limits: Do not run gears beyond rated loads (overload increases wear).

Tooth Bending (Breakage) Prevention

Adequate Gear Design: A proper safety factor in design, deeper tooth roots, and correct tooth geometry all reduce bending stresses.

Material Strength: Use tough, fatigue-resistant materials (alloy steels) and surface treatments to boost strength.

No Overloads: Prevent shock/all-at-once loads and oversized torques which could snap teeth (use torque limiters if needed).

Correct Alignment: Misalignment places extra bending stress on gear teeth, so ensure precise installation and routine checks.

Tooth Fatigue (Surface Pitting/Cracking) Prevention

Material Quality: Choose high fatigue strength materials, possibly with case hardening for a tough surface/ductile core.

Smooth Tooth Finish: Surface finishing and proper grinding minimize flaws that initiate cracks.

Lubrication: Adequate lubrication lowers friction and temperature—both critical for limiting fatigue damage.

Load Uniformity: Try to avoid repeated heavy or fluctuating loads, which accelerate fatigue.

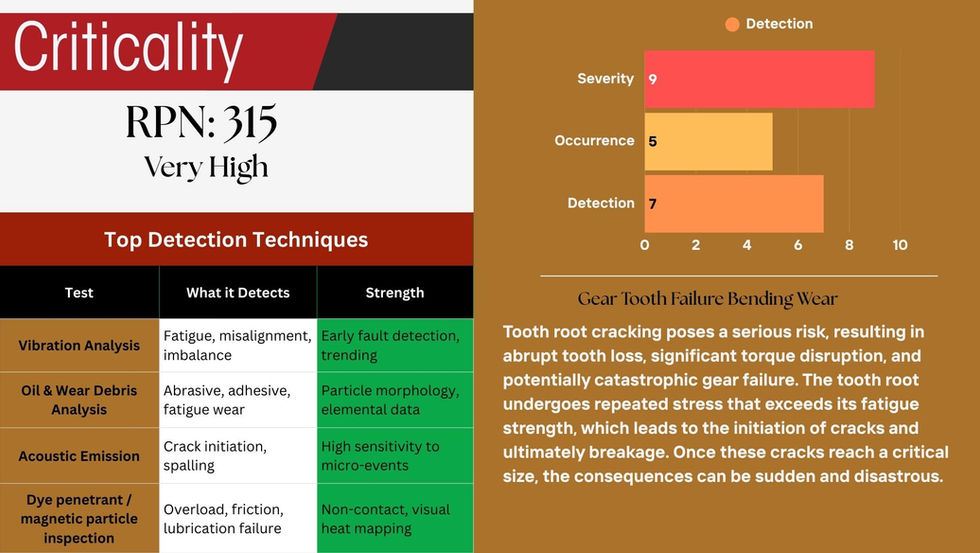

Periodic Inspections: Use vibration analysis, dye penetrant, or magnetic particle inspection to catch early fatigue signs.

Root Causes

Overload or Shock Loading: sudden or repeated torque spikes exceeding gear design limits.

Misalignment: Uneven load distribution across the gear tooth root, causing localized overstress.

Material defects: Inclusions, voids, or poor heat treatment leading to weak tooth roots.

Improper Design: Insufficient tooth root thickness or incorrect gear geometry.

Fatigue From Cyclic Stresses: Repeated bending loads leading to crack initiation at the root.

Poor Lubrication: Increased friction, wear, and secondary stresses at the tooth contact area.

Surface Wear (Abrasive/Adhesive): Thinning or weakening of tooth material that accelerates bending failure.

Excessive Vibration: Resonance or torsional oscillations amplifying tooth root stresses.

Corrosion or Chemical Attack: Pitting and loss of cross-sectional strength at the tooth base.

Thermal Stresses: Overheating or uneven thermal expansion leading to stress concentrations.

Description

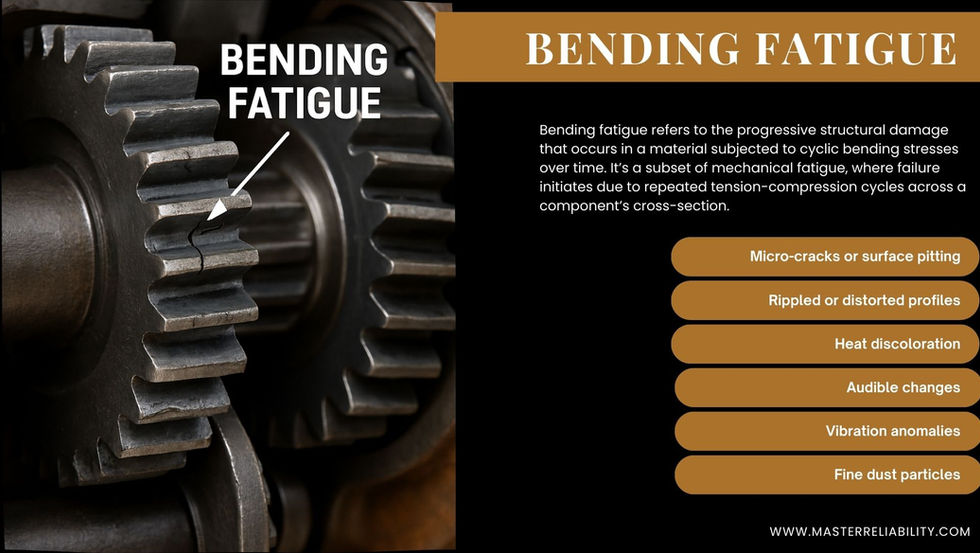

Bending fatigue refers to the progressive structural damage that occurs in a material subjected to cyclic bending stresses over time. It’s a subset of mechanical fatigue, where failure initiates due to repeated tension-compression cycles across a component’s cross-section.

Go / No Go

The triggers listed below, indicate when corrective action must be taken to avoid catastrophic failure or when operation should be stopped for maintenance.

Bending Failure Triggers

Crack Detection: Any visible crack in the root or on the flank of the tooth detected during visual or dye-penetrant inspection must immediately trigger a stop and repair.

NDT (Non-Destructive Testing) Results: Any positive result for cracks or flaws in gear teeth root region from magnetic particle or ultrasonic testing.

Excessive Tooth Deflection: Unusual deflection/backlash outside manufacturer tolerance.

No Go Triggers for GearTooth Failures

Tooth Wear (Surface Wear) Triggers

Maximum Allowable Wear: If tooth thickness is reduced by more than 10-15% from nominal by wear (measured with calipers, gauges, or profile tracers).

Visible Scoring or Excessive Polishing: Presence of deep scratches, scoring, or abnormal surface polish indicating lubricant failure or abrasive ingress.

Oil Analysis Contaminant Levels: Detection of metallic particles in oil exceeding OEM/industry-recommended limits.

General No Go Triggers

Oil Temperature: Oil temperature consistently > specified safe limit (e.g., >90°C for most industrial boxes unless otherwise stated).

Lubrication Loss: Failure or significant drop in oil pressure/flow.

Unusual Vibration: Spike in overall vibration (>ISO 10816 severity limits for gears).

Unexpected Backlash Increase: Sudden increase in gear backlash or endplay.

Action Plan on No Go

Stop Operation: If “No Go” is triggered, IMMEDIATELY stop the gearbox.

Document & Inspect: Record the trigger event, inspect components, and plan maintenance or repairs.

Root Cause Analysis: After repair, determine and address the underlying cause to avoid recurrence.